The typical alloying elements are copper magnesium manganese silicon tin and zinc. Cast Aluminum Alloys These are used for parts of complex shapes by sand casting permanent mold casting and die casting.

Aluminum Alloys Wrought And Cast Property Data

In this article the base metal in question is aluminum and these unique elements can be silicon copper zinc andor many other metallic elements.

Aluminum alloy material properties. Material properties are intensive properties that means they are independent of the amount of mass and may vary from place to place within the system at any moment. But when alloyed aluminium alloys are heat treatable which significantly changes theri mechanical properties. 7075 aluminium alloy AA7075 is an aluminium alloy with zinc as the primary alloying element.

6061 Aluminum Alloy Composition by Mass Al Mg Si Fe Cu Cr Zn Ti Mn Remainder 9585 - 9856 Properties. Youngs Modulus is 69 GPa 10000 ksi regardless of temper. However the addition of alloying elements like manganese silicon copper and magnesium can increase the strength properties of aluminium and produce an alloy with properties tailored to particular applications.

Aluminum alloys are second only to steels in use as structural metals. It has excellent mechanical properties and exhibits good ductility high strength toughness and good resistance to fatigue. Properties of Aluminium Alloys High purity aluminium is a soft material with the ultimate strength of approximately 10 MPa which limits its usability in industrial applications.

Aluminium of commercial purity 99-996 becomes harder and stronger due to the presence of impurities especially of Si and Fe. Aluminum has good corrosion resistance to common atmospheric and marine atmospheres. Aluminium is easy to recycle and has a low density a third that.

It is widely used in industry and is used second only to steel. Aluminum has a density of only 27 gcm3 approximately one-third as much as steel 783 gcm3. Bradley Fighting Vehicle The military Bradley Fighting Vehicle is made from two different aluminum alloys.

Welded aluminium alloy bicycle frame made in the 1990s. Annealed 6061 6061-O temper has maximum ultimate tensile strength no more than 150 MPa 22 ksi and maximum yield. 1 psi lbin2 68948 Pa Nm2.

The properties of aluminium - Aluminium Design The properties of aluminium include corrosion resistance durability low weight and high strength. The basis of materials science involves studying the structure of materials and relating them to their properties mechanical electrical etc. Aluminium alloys are based on aluminium in which the main alloying elements are Cu Mn Si Mg MgSi Zn.

A cubic foot of aluminum only about 170 lb. One cubic foot of steel weighs about 490 lb. But when alloyed aluminium alloys are heat treatable which significantly changes theri mechanical properties.

Aluminium alloys or aluminum alloys. 6061 Aluminum Physical Properties 6061 aluminum physical properties are given in the following lists including density melting point coefficient of thermal expansion elastic modulus thermal conductivity specific heat capacity electrical conductivity and electrical resistance. A 7xxx series and 5xxx series.

Pure aluminium doesnt have a high tensile strength. Aluminium is well suited to cold environments. Modern commercial aluminum comes in many types known as alloys and each provides unique benefits depending upon the alloy chosen.

Engineering Materials Manufacturing Processes. See spelling differences are alloys in which aluminium Al is the predominant metal. Chemical Composition and Properties of Aluminum Alloys The Benefits of Aluminum Aluminum is a light metal about the third of the density of steel copper and brass.

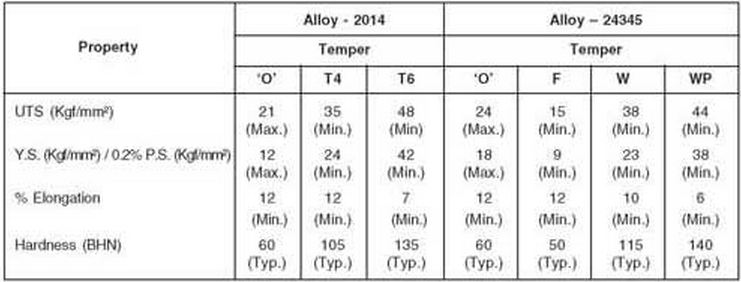

Mechanical properties for some aluminum alloys. Aluminum material properties. Aluminium of commercial purity 99-996 becomes harder and stronger due to the presence of impurities especially of Si and Fe.

It has the advantage over steel in that its tensile strength increases with decreasing temperature while retaining its toughness. Aluminium of commercial purity 99-996 becomes harder and stronger due to the presence of impurities especially of Si and Fe. If you have any questions or good suggestions on our products and site or if you want to know more information about our products please write them and send to us we will contact you within one business day.

Aluminium alloys are based on aluminium in which the main alloying elements are Cu Mn Si Mg MgSi Zn. Mechanical Properties of Aluminum Sand Castings. Material properties The aluminum alloy has low density but high strength close to or exceeds high-quality steel good plasticity can be processed into various profiles has excellent electrical conductivity thermal conductivity and corrosion resistance.

Chat Now Send Inquiry. The mechanical properties of 6061 depend greatly on the temper or heat treatment of the material. Mechanical Properties of Aluminum Sand Castings.

An alloy is an enhanced engineering material made by adding unique elements into a base metal. Aluminums properties such as strength density workability electrical conductivity and corrosion resistance are affected by adding other elements such as magnesium silicon or zinc. Properties of Aluminium Alloys.

Such light weight coupled with the high strength of some aluminum alloys exceeding that of struc-.