When metal-on-metal MoM hip implants were first introduced in the mid 2000s they were hailed as medical breakthroughs that would last longer than traditional hip replacements and allow patients to lead more active lives. A metal-on-metal MoM pseudotumor also known as aseptic lymphocyte-dominant vasculitis-associated lesion ALVAL is a mass-forming tissue reaction c aused by metal-on-metal wear the lesion is neither infective or neoplastic and develops in the vicinity of a total hip replacement THA.

Metal On Metal Hip Implant Systems Fda

Metal On Metal Hip Implant Systems Fda

Most people who have a metal-on-metal MoM implant have well-functioning hips and are thought to be at low risk of developing any serious problems.

Metal on metal hip. Metal-on-metal MoM hip implants have unique risks in addition to the general risks of all hip implants. Some patients who had a hip replacement prior to May 182016 may have received a metal-on-metal hip implant. When hip implants first became popular patients had the option of choosing either a plastic or ceramic implant system.

Hip revision surgery especially for metal-on-metal hip implants carries a higher risk of infection blood clots bone fractures and other surgical complications than a regular hip replacement. Furthermore robust thresholds for performing ARMD revision are lacking. This is largely due to the fact that the procedure takes longer and is more complicated than a first hip replacement.

Metal on Metal Hip Implants Designed to Last For Years. Each 1 mm 0039 in increase in head size of metal-on-metal hip implants was associated with a 2 increase of failure. Metal devices were designed to provide patients with an implant that would last for years.

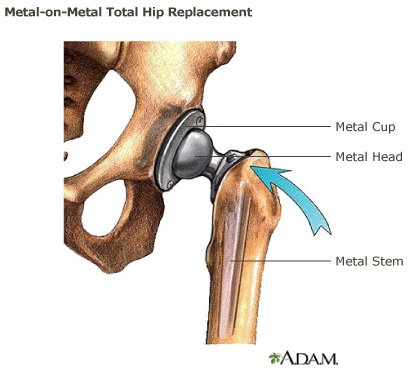

A metal-on-metal hip implant consists of a ball and cup made of a cobalt and chromium alloy. MHRA is updating advice provided in MDA2012036 to assist the early detection of soft tissue reactions in patients implanted with metal-on-metal MoM hip replacements MDA2017018. Over time it became clear that these materials were not particularly durable.

Reports of patient reactions to these ions have spurred the FDA to order the 21 makers of these devices to perform new. Your hospital will always have a record of your operation and what implants were used. Metal-on-metal implants are also used for hip resurfacing implants.

There are some case reports of the metal particles causing a reaction around the joint leading to deterioration of the tissue around the joint loosening of the implant and failure of the device as well as some of the symptoms described above. The information on failures of Metal on Metal implants accumulated slowly as is always the case but came to a point when based on Joint Registry data in Australia and the UK one implant in particular De Puys ASR system was identified as performing significantly less well than others used to replace painful arthritic hip joints. All hip resurfacing operations use a metal-on-metal bearing hip.

With more and more people getting hip implants overall and more younger patients needing implants that could last a long time metal-on-metal became a popular choice for surgeons and their patients. Metal-on-metal bearings34 Moreover adverse periprosthetic tissue reactions involving the hip joint have emerged as an important reason for failure in MoM patients. On 29 June 2017 the UK Medicines and Healthcare Products Regulatory Agencys MHRA published updated advice regarding metal-on-metal MoM hip replacement implants.

Metal-on-metal hip implants like other types of hip implants are known to have adverse events including infection and joint dislocation. Metal-on-metal implants use a similar design to standard hip replacements but the surfaces of both the ball and the socket are made of metal. The TGA review of that advice which included referral to an external group of experts found that the.

Metal-on-metal hip replacements have been done for many years. This article is the second of 2. Most total hip replacements are not metal-on-metal bearings and use other materials including ceramic and high density polyethylene.

Update 14 July 2017 Metal-on-metal hip replacement implants 20 September 2012 Update. At the same time metal-on-metal hip implants were being touted as durable and reliable implants due to their design and materials. But compared with other hip replacements some metal-on-metal hip devices have been found to wear down more quickly in some patients.

Background and purpose - The initial outcomes following metal-on-metal hip arthroplasty MoMHA revision surgery performed for adverse reactions to metal debris ARMD were poor. There are two FDA-approved metal-on-metal hip resurfacing devices available. Originally developed as a more durable alternative to implants with ceramic or polyethylene plastic components MoM implants proved to be the opposite.

The information provided in this white paper is intended as an aid to the orthopaedic surgeon in the assessment and management of patients with metal-on-metal bearings. The first artic. Metal-on-metal hip replacements release metal ions into the bloodstream.

In MoM hip implants the metal ball and the metal cup slide against each other during. The analysis of 402051 hip replacements showed that 62 of metal-on-metal hip implants had failed within five years compared to 17 of metal-on-plastic and 23 of ceramic-on-ceramic hip implants.

Stainless steel while corrosion resistant is still in the ferrous metal family. The use of ferrous metals started in around 1200 BC when iron production started to become commonplace.

The Difference Between Ferrous And Non Ferrous Metal Non Ferrous Metals Metal Power Engineering

The Difference Between Ferrous And Non Ferrous Metal Non Ferrous Metals Metal Power Engineering

As a leading steel merchant we keep a full range of high-quality products in stock for our customers.

Is stainless steel a non ferrous metal. Think steel stainless steel carbon steel cast iron. These metals are prized for their tensile strength and durability. Important non-ferrous metals include aluminium copper zinc titanium lead tin nickel and alloys such as brass.

Ferrous metals are prone to the risk of rusting because of their high carbon content. Making Sure You Have the Right Alloy for the Right Application in our sister blog Analyzing Metals. This ushered in the Iron Age.

There are many types of stainless steel and they all vary on their strength scratch resistance corrosion resistance and more. Medium carbon steels are mainly used for making different automotive industry components like gears axles shafts but also bolts nuts screws etc. Non-ferrous alloy harder than brass and corrosion resistant reddishyellow in colour Castings bearings Stainless steel alloy of steel also with chromium nickel and magnesium.

However the addition of small amounts of chrome nickel etc result in the properties of stainless steel. These metals are prized for their tensile strength and durability. A lot of the scrap metal that we recycle and process are non-ferrous metals.

Benefit from our many years of experience in dealing in stainless steel and aluminium. Some non-ferrous metals are made for cryogenic applications others are made to withstand extremely. Stainless steel has a base of ferrous.

Some non-ferrous metals are hard and brittle some soft and ductile. The iron content of stainless steels is about 70. It is nearly impossible to define the common properties of non-ferrous metals simply because there is such a large variety of metals that fall into the non-ferrous category.

This ushered in the Iron Age. Historical price data is only for members please. Aluminum which do not have iron ferrous metals are prone to rust when exposed to even slight amounts of moisture.

Non-ferrous metals by definition are metals including alloys that does not contain iron in appreciable amounts. Thanks to their magnetic properties ferrous metals are also used in appliances and engines. 304 Scrap Stainless Steel Cut-Off price historical Data.

It is nearly impossible to define the common properties of non-ferrous metals simply because there is such a large variety of metals that fall into the non-ferrous category. We supply from stock. Stainless steels are renowned for their superior corrosion resistance which increases with increasing chromium content.

Some common ferrous metals include alloy steel carbon steel cast iron and wrought iron. Some non-ferrous metals are hard and brittle some soft and ductile. Base metals on SHFE were mostly higher as the US dollar fell to two-week low SMM Evening Comments Feb 9.

Stainless steel Non-ferrous metals Just ask us. Some non-ferrous metals are made for cryogenic applications others are made to withstand extremely. Steels ranging from 0406 are also suitable for everything related to locomotives and rails.

However some grades of stainless steel are an exception because of the presence of chromium. Ferrous Metals Ferrous metals contain iron and are known for their strength. Therefore stainless steels are ferrous metals as their main constituent is iron even in the very highly alloyed grades such as super duplex stainless steels or super austenitic stainless steels.

The exceptions to this rule are wrought iron and stainless steel. Wrought iron resists corrosion because its levels of carbon are extremely low meaning that it is almost purely iron. Ferrous metals include mild steel carbon steel stainless steel cast iron and wrought iron.

Ferrous metals can be easily made less corrosive by adding other elements or by cathodic protection. Non-ferrous metals would include aluminium copper lead tin and zinc. Non-ferrous metals include aluminum brass copper nickel tin lead zinc and precious metals.

So stainless steels are ferrous metals. Which Metals Are Ferrous. Ferrous metals are used in both architectural and industrial fabrication such as skyscrapers bridges vehicles and railroads.

Stainless steel is a carbon steel alloy with at least 105 of chromium by mass. If you are really interested in knowing more about the different types of metals read Ferrous Metals Analysis. This steel alloy is usually combined with other elements such as molybdenum and nickel to further enhance corrosion resistance.

By far the largest element is iron. Is stainless steel ferrous metal or non ferrous metal. Some common ferrous metals include engineering steel carbon steel cast iron and wrought iron.

It is an alloy that is chemically made to have a high resistance to corrosion and is extremely strong. The use of ferrous metals started in around 1200 BC when iron production started to become commonplace. Compared to non-ferrous metals eg.

Since we are a specialist scrap metal recycling and processing facility we operate a non-ferrous division where we can buy recycle and process various grades of non-ferrous metal including aluminium copper brass stainless steel and lead. Gears shafts and axles all ferrous metal. That means each type of ferrous and non-ferrous metal has different qualities and uses.

Stainless steel is another ferrous metal that wont rust.

Our liquid metal coatings can be applied to any surface even. Our certified Precision Liquid Spray Coating Process serves a variety of industries- including aerospace.

Rust Oleum Review Five Metallic Grey Spray Paints Comparison Youtube

Rust Oleum Review Five Metallic Grey Spray Paints Comparison Youtube

Use our various metals types to achieve realistic stunning effects that could never be achieved by using metallic paint chrome spray finishes powder coatings metallic paint or sheet metal.

Liquid metal spray paint. It is a patented cold sprayable metalizing process comprised of up to 75 pure metal. This just means there is no heat involved in the process of spraying so there will not be any size reduction twisting distortion or cosmetic impact at all on the final product. They are cost-effective durable and beautiful.

The metal coatings can be applied onto virtually any surface such as timber plastic MDF fibrecement fabric and paper in millimeter thickness to create a look and feel of solid metal. Add to that the latest exciting launch PURE METALS the first Liquid Metal Coating which has been specifically designed for walls furniture interior features. HYPERSILVER micro metal produces an elegant polished metal custom finishThis custom paint cannot be confused with a conventional silver metallic.

No it is not metal paint. Rose gold spray paint spray paint gold spray paint rustoleum spray paint flatmatte metallic paint purple pearl metallic. Our liquid metal coatings can be applied to any surface even.

Metall-FX offer bespoke and specialised metal finishes to clients who are after a unique and one-of-a-kind concept which is born and brought to life through our team of talented artisans. Stephan Schwarte head of Color Design at BASF Coatings explains how the successful integration of a special-effect pigment into a waterborne paint system p. MTL Coatings Cold Spray Metals are cost-effective durable and naturally beautiful.

Get free shipping on qualified Liquid Metallic Paint or Buy Online Pick Up in Store today in the Paint department. Hold the primer 6 to 8 15 to 20 cm inches away from the surface and spray. Use them instead of metallic paint chrome spray finishes powder coating metal paint chrome paint sheet metal and Corten steel.

PURE METAL is a solvent free system when used for trowel application and as such offers a massive range of options for on site use. Prime the metal surface with spray-on primer. PURE METAL is an exclusive collection of Liquid Metal Coatings that produce an authentic textured metal finish from antique to a brilliant metal shine with endless application possibilities.

When applied these liquid metal coatings will bring a touch of elegance and classiness to any surface and these spray-on metal paints are true liquid metals. Get free shipping on qualified Metal Spray Paint or Buy Online Pick Up in Store today in the Paint department. All safe for on site application.

Each paint imitates an authentic look and feel of typical surfaces found in urban environments from rust to natural stone. You can use the spray primer of your choiceas as long it is made to be used on metal. Liquid Metal Liquid Metal is a range of unique sprayable and brushable metals that are applied using a cold-spray coating process that cures at room temperature.

You can apply it directly over rusted metal steel surfaces or existing paint with no sandblasting required. Copper and Robbers Liquid Metal Paint 400ml Spray Can ONLY AVAILABLE IN UK EUROPE Copper and Robbers is a fabulous new real copper paint specially developed to get the perfect real c. There are several powder coaters around the area but there are only a few liquid coaters around.

Metal Effects Blue Patina Paint Oxidizing Finish Kit Model 306291 20 71. Thats why Pilkington maintains its own paint department for applying a wide variety of colors decorative and graphic effects to aluminum as well as steel plastics. Paint the entire surface.

With a 15000 hour salt spray test ASTM B117 rating Rust Grip is therefore one of the most effective anti-rustanti-corrosion coatings. They are cost-effective durable and beautiful. Liquid Metal Spray Paint Liquid Metal Spray Paint Suppliers Directory - Find variety Liquid Metal Spray Paint Suppliers Manufacturers Companies from around the World at spray paint paint spray guns spray paint machine Building Coating.

These liquid metal spray paints are also not heavy and weighty and are exceptionally tough. Use them instead of metallic paint chrome spray finishes powder coating metal paint chrome paint sheet metal and Corten steel. Spray painting is something that sets us apart from other paint shops.

Industrial spray painting involves spray-applied enamels epoxies polyurethanes and lacquers on metal plastic or wood surfaces. The end result is an extremely realistic metal appearance. Metalier Coatings are a sprayable liquid metal system which can make any substrate look like solid metal.

Formerly known as Alumifec HR. Modern Masters 2 oz. It is an alternative to chrome plating foundry metal metallic paint finishes plating and other metalizing processes.

Liquid metal spray paints are cold-spray paints. Using a primer is necessary to ensure that the final paint job is smooth and even. Aesthetics are an important part of most projects.

The almost magical properties of the Metall-FX product means that you can choose from dozens of pure metals and alloys then choose a different texture colour and have it finished in a manner totally unique. Metalier Coatings are a sprayable liquid metal system which can make any substrate look like solid metal.

Loctite Epoxy Metal Concrete does not conduct electricity which is ideal for sealing electrical components. The convenient syringe dispenses equal amounts of each component every time.

Holiday Concrete Epoxy High Viscosity Hv 1 Gallon Lazada Ph

Holiday Concrete Epoxy High Viscosity Hv 1 Gallon Lazada Ph

The injection resin shall be a two component epoxy adhesives which has the capability to bond to concrete wood or steel surfaces.

Metal to concrete epoxy. It cures to a metallic gray finish and can be easily sanded or machined. Steel Plus Epoxy Primer is a fast drying two-component water-based epoxy primer for metal and concrete surfaces. Loctite Epoxy MetalConcrete does not conduct electricity which is ideal for sealing electrical components.

Recommended for bonding Metals Ceramics Stone Glass Concrete Wood Fiber. Find or specify kiln-dried sand or aggregate in sealed bags. The strength of a bonding joint if made properly will always far exceed that of even the best quality concrete.

Scratching the surface of the plastic will increase the surface area increasing the strength of the bond between plastic concrete. When mixed in equal volumes resin and hardener react to produce a tough rigid high strength bond in 5 to 12 minutes. Hold the putty knife at an angle and use the metal blade to scrape and lift the epoxy.

The epoxy based compounds will have high strength at a very early age and extreme chemical resistance which measure that a bonded joint will remain unaffected by environmental contamination. Below is a comparison of the same adhesive types for both non-polar solvents. The biggest challenges are 2 fold in my opinion.

If you want to add aggregate or sand to a liquid epoxy to make a mortar or grout or to extend the epoxy volume the best policy is to use aggregate that contains less than 02 moisture. So far weve determined that one part epoxy is the strongest glue for metal to metal and it is a high heat resistant adhesive the third factor in selecting metal glue is chemical resistance and once again one part epoxy lead the pack. So you need to make sure that it can resist heat and water well.

FREE Shipping on orders over 25 shipped by Amazon. Get it as soon as Fri Feb 12. Waterproof Glue Alco-Flex Polyurethane Adhesive Sealant Build Fix-All Gripfill Rapid Epoxy.

Such as Kemko 038. It is used as an adhesive for repairing filling and rebuilding all metal and concrete surfaces. Epoxy differs from glue in that its components must be stored separately to prevent curing before use.

The following Bostik and Alcolin products are recommended for sticking Metal to Cement Concrete Brick. It does not shrink and is resistant to water and most common solvents. It must ensure that it will set quickly and last for a long time.

There are epoxies used on concrete anchors improving the hydraulic force between the concrete and fastener. We all know that metal is a heat conductor and obviously it will come in contact with water as well. Structural adhesives and epoxies are available for bonding automotive plastic components filling cracks in concrete connecting metal components and more.

It has excellent rust inhibitive qualities is also low odor and HAPs free. When mixed in equal volumes resin and hardener react to produce a tough rigid high strength bond in 5 to 12 minutes. Loctite Epoxy MetalConcrete is a two-part system consisting of an epoxy resin and a hardener.

The first deals with the thermal coefficient of contraction and expansion. It mixes 4 parts epoxy to 1 part curing agent and is easy to apply and provides about a 2 to 4 hour pot life depending on surrounding temperatures. The convenient syringe dispenses equal amounts of each component every time.

Features and Benefits Loctite Epoxy Metal Concrete is a two-part system consisting of an epoxy resin and a hardener. Kits for concrete repair are available handling cracks up to 14 inch wide. We would suggest metal epoxy with- easy usability quick-set ability decent strength water and heat resistivity.

Adiseal is suitable at bonding most types of plastics to concrete. Use a toothbrush or toothpick to remove the epoxy located in small dents and crannies. Loctite Metal and Concrete Epoxy Syringe 25-Millileters 1919325 2 40 out of 5 stars 19.

For injection of cracks up to 14 inch cold joints delaminations and holes above 40F the two component epoxy adhesive shall have a mixed viscosity from 200 to 350 cps at 73F. More Buying Choices 1080 2 new offers Loctite 1919325-8 Metal and Concrete Epoxy Syringe 25-Millileter Syringes Case of 8 Medium Grey. Recommended for bonding metal and concrete as well as glass ceramic and wood.

Prepping the Concrete Surface You should start by cleaning the crack area extending up to half an inch to each side of the crack. It does not shrink and is resistant to water and most common solvents. When steel in embedded in the concrete like re-bar it is surrounded and insulated by the concrete.

It cures to a metallic gray finish and can be easily sanded or machined. As with metal clean the plastic thoroughly to make sure any dust oil grease paint or any other dirt is removed before applying the adhesive. Concrete cracks due to corroded steel should not be repaired using the epoxy as the steel will continue to decay and new cracks will appear.

Two Part 5 Minute Epoxy Adhesive C-Poxy 5 by CECCORP is a 85 oz General Purpose Structural-unfilled-Fast Setting epoxy. Once youve successfully removed the epoxy paint find a way to clean concrete garage floor.